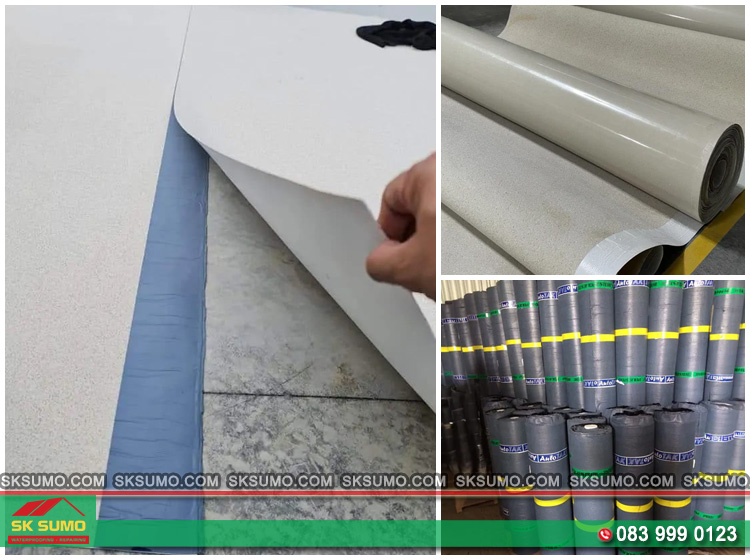

Roll 50-100m, thick 1.2mm

In waterproofing works for foundations, basements and concrete structures, choosing the right base material is critical to long-term durability and structural safety. When referring to high-quality engineering plastic membranes, many engineers and contractors tend to prioritise products meeting international standards to minimise risks of reverse seepage, hydrostatic leakage or capillary moisture. This is why HDPE membranes from the Fosroc brand have become increasingly sought after.

The HDPE Fosroc 1.2mm waterproofing membrane is a synthetic polymer made from high-density polyethylene (HDPE) resin, offering high tensile strength, puncture resistance and complete water impermeability thanks to its tightly bonded molecular structure and chemically resistant surface. It is specifically designed for waterproofing applications in construction, especially in areas exposed to high water pressure or corrosive environments.

In terms of material properties, Fosroc HDPE stands out for its superior surface uniformity and tensile strength compared to conventional HDPE, achieved through a three-layer extrusion process meeting international standards. The 1.2mm thickness provides a balanced combination of waterproofing capability, installation ease and cost-effectiveness for various projects. The material is also valued for its long lifespan, minimal deformation under high temperatures and strong resistance to mechanical stress from soil or freshly poured concrete.

In addition to waterproofing performance, Fosroc 1.2mm also offers UV resistance, acid-alkali resistance and immunity to biological degradation, enabling long-term structural durability. With its stable molecular structure and ability to perform under harsh conditions, this membrane is regarded as a suitable choice for projects requiring high quality and structural safety.

When evaluating the real-world performance of a plastic membrane, its structure and technical specifications play an essential role. Many leakage incidents originate from using materials with low density or insufficient surface strength. Therefore, understanding the composition of the HDPE Fosroc 1.2mm membrane is the foundation for assessing its durability and application range.

The Fosroc HDPE membrane is produced from virgin high-density polyethylene resin with high density and tight molecular bonding. During extrusion, UV stabilisers, heat stabilisers and tensile-strength-enhancing additives are added to ensure long-term performance in construction environments. Thanks to its high virgin resin content, the material has exceptional longevity and minimal degradation when exposed to chemicals.

The distinctive advantage of Fosroc lies in its controlled molecular-density manufacturing process, creating a smooth surface with minimal air pockets and excellent puncture resistance. The membrane surface resists cracking, ageing and brittleness under temperature changes. This makes Fosroc 1.2mm suitable for areas requiring high water-tightness or those subject to substrate movement such as wall-floor joints and footing edges.

Key technical metrics include minimum tensile strength, elongation, puncture resistance, water vapour barrier performance and chemical resistance. Fosroc 1.2mm offers high tensile strength, excellent elongation and superior water-pressure resistance compared to standard materials. These specifications ensure the membrane remains intact during concrete pouring or when withstanding soil loads.

In actual construction, many investors often question the differences between branded products and regular HDPE membranes. Misunderstanding these differences can lead to the selection of unsuitable materials, causing high repair costs or reduced structural lifespan. Clear differentiation allows accurate assessment of the advantages of the HDPE Fosroc 1.2mm waterproofing membrane over common products on the market.

Differences in manufacturing technology

Fosroc manufactures HDPE membranes using a multi-layer extrusion process with automated control to ensure surface uniformity and molecular density stability. Meanwhile, common products are often single-layer extruded with limited control over temperature and pressure, resulting in significant differences in waterproofing performance, tensile zones and puncture resistance. Fosroc also incorporates high-quality UV and antioxidant additives, delivering better outdoor durability.

The Fosroc 1.2mm membrane has superior tensile strength and elongation, reducing the risk of tearing under load variations or during concrete placement. Its smooth, low-porosity surface minimises the formation of weak points during installation. In contrast, standard HDPE membranes are more easily affected by acidic, alkaline or constantly humid environments, leading to faster ageing and reduced waterproofing performance over time.

Fosroc maintains stable waterproofing performance due to its molecular structure, which withstands high hydrostatic pressure and reduces vapour transmission. This is crucial for areas such as basements or tanks where water pressure is continuous. Standard HDPE membranes may meet basic requirements but struggle to maintain long-term efficiency in high-pressure or corrosive environments.

When assessing long-term waterproofing effectiveness, it is not only the material specifications but also its compatibility with specific applications that determine success. Many installers rely on habit rather than evaluating the actual exposure conditions, resulting in reduced structural lifespan. Understanding typical applications of the HDPE Fosroc 1.2mm membrane helps optimise effectiveness and investment costs.

In foundations and basements, the membrane must resist reverse seepage, hydrostatic pressure and substrate movement. Fosroc 1.2mm, with its high tensile strength and puncture resistance, stabilises the surface when in contact with soil or concrete. In technical tanks such as domestic water tanks, fire-fighting tanks or light-solution reservoirs, HDPE ensures complete watertightness and reduces chemical attack risks.

For large-area concrete structures such as roofs and industrial floors, temperature changes may cause surface expansion leading to micro-cracks. Fosroc 1.2mm, with its high elongation rate, absorbs thermal movement and prevents membrane damage. In flat roofs or areas prone to stagnant water, its stable molecular structure provides long-term waterproofing performance.

In waste-treatment and environmental projects, membranes must resist acids, alkalis and chemicals from waste. Fosroc 1.2mm, with its chemical-stabilising additives, effectively withstands attacks from organic and inorganic compounds. It is a suitable choice for sanitary landfills, leachate ponds and other high-load environmental zones.

In many projects, incorrect material selection stems from misunderstandings regarding features and application boundaries. Technically unsupported assumptions may expose contractors to leakage risks, increased costs and extended schedules. Identifying and clarifying these misconceptions enables proper and effective use of the HDPE Fosroc 1.2mm waterproofing membrane.

Some assume all HDPE types can be used for fish ponds or aquaculture tanks. In reality, Fosroc is engineered for construction and not optimised for aquaculture, which requires higher flexibility and ductility. This misconception often leads to suboptimal performance.

Many believe thicker membranes are always more durable, but thickness is only one parameter. Lifespan depends heavily on molecular density, UV stabilisers and tensile strength. Fosroc, with its stable structure, can perform better than a thicker but lower-quality membrane.

Many leakage issues arise from poor installation practices such as unsealed joints, incorrect wall-base treatment or failure to protect the membrane before concrete pouring. Although Fosroc is highly durable, improper installation significantly reduces its waterproofing effectiveness.

Many investors and engineers aim to evaluate materials based on objective criteria to ensure compatibility with project requirements. With various HDPE types available at different price points, selecting a certified, high-quality product helps avoid waste and operational risks. The criteria below support choosing the appropriate HDPE Fosroc 1.2mm membrane.

One of the most important factors is the manufacturer’s quality certifications, including international standards for tensile strength, elongation, puncture resistance and chemical resistance. Fosroc meets these requirements through modern production and strict quality control.

When assessing a material, soil type, load direction, humidity and chemical exposure must be considered. Fosroc 1.2mm is suitable for environments with significant temperature fluctuations and areas under prolonged load, ensuring stability during construction and operation.

Choosing a cheap but low-quality material may result in much higher repair costs later. Fosroc, with its long lifespan and long-term stability, optimises maintenance expenses and reduces leakage risks throughout its service life.

A clear understanding of the structure, advantages and application range of the HDPE Fosroc 1.2mm waterproofing membrane allows for better material selection across various construction elements. This product is highly regarded for its mechanical strength, durable waterproofing and stability under harsh conditions. Selecting the proper Fosroc membrane not only enhances waterproofing quality but also optimises long-term maintenance costs. If you wish to explore additional engineered membranes, you may refer to other HDPE types with different thicknesses or standards for a more complete overview.

Currently, Fosroc 1.2mm HDPE waterproofing membrane costs from 145,000 VND/m2, excluding VAT and total construction cost from 300,000 VND/m2.

The surface must be clean, relatively flat, free of sharp objects and with proper drainage slope to avoid creating local pressure points on the membrane.

Welds can be checked immediately after welding using a vacuum test or air-pressure test, without waiting time, due to the membrane’s good thermal stability.

Use a high-voltage holiday detector (spark test) to locate any gaps and ensure complete watertight integrity.

Because it maintains thermal stability, has high tensile strength and long-term ageing resistance, meeting durability requirements for demanding projects.