In aquaculture ponds, landscape lakes, and basements, choosing the wrong waterproofing membrane can lead to leaks, blistering, and foundation damage, resulting in costly repairs. This is why engineers often prioritize Aritex HDPE waterproofing membrane thanks to its stable durability, high UV resistance, and consistent material quality. When making a decision, users typically compare real-world performance and pricing by thickness to ensure long-term operational safety.

Aritex HDPE waterproofing membrane is regarded as one of the most stable materials for construction and industrial ponds. Before selecting it, users need to understand its origin, material structure, and certified standards. These factors form the basis for evaluating real-world performance across various types of projects.

Aritex HDPE waterproofing membrane is manufactured under ASTM and ISO standards using a three-layer blown extrusion line. In many countries, these are the fundamental standards applied to geomembranes used in construction, wastewater treatment, and aquaculture.

The material is made from high-density polyethylene with no recycled impurities, low tolerance deviation, and is supported by independent laboratory test certifications. Clear origin information helps reassure users in safety-critical applications.

The polymer core of Aritex HDPE waterproofing membrane provides chemical resistance, puncture resistance, and excellent tensile strength. Its average tensile strength exceeds 25 MPa, with elongation reaching about 700% according to ASTM D6693 testing.

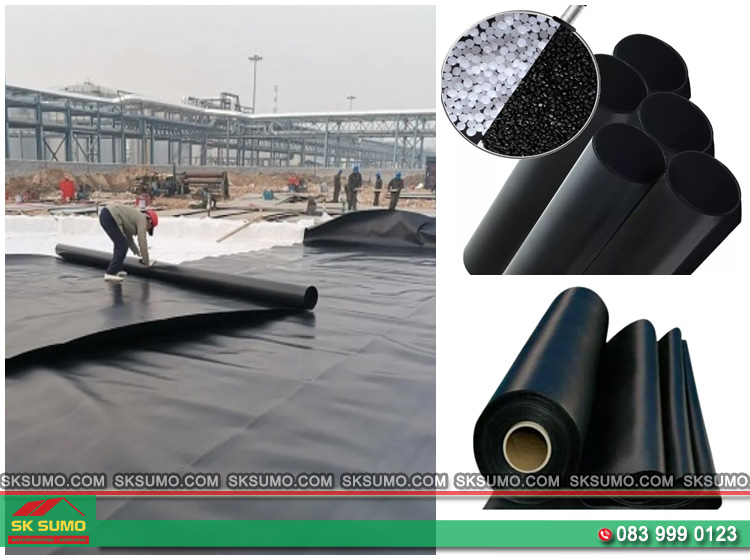

Thanks to its dense molecular structure, the membrane offers near-absolute impermeability with an extremely low permeability coefficient. This is why the material is widely used in water reservoirs, sanitary landfills, landscape ponds, and industrial shrimp ponds.

One of the major advantages of Aritex HDPE waterproofing membrane is its long outdoor lifespan due to strong UV resistance. It experiences minimal deformation under thermal impact, withstands chemicals, and tolerates high ground loads.

With proper installation, Aritex can achieve an actual operating lifespan of 15–25 years depending on location and UV intensity.

In engineering assessments by contractors and investors, Aritex HDPE waterproofing membrane is often favored for its mechanical durability and stable waterproofing ability. The factors below determine its long-term performance.

Carbon black particles in the polymer structure help Aritex HDPE waterproofing membrane maintain stability under direct sunlight and retain long-term tensile strength.

In UV 4.3 accelerated aging tests, the material shows very low mechanical degradation, making it suitable for installation in high-radiation regions.

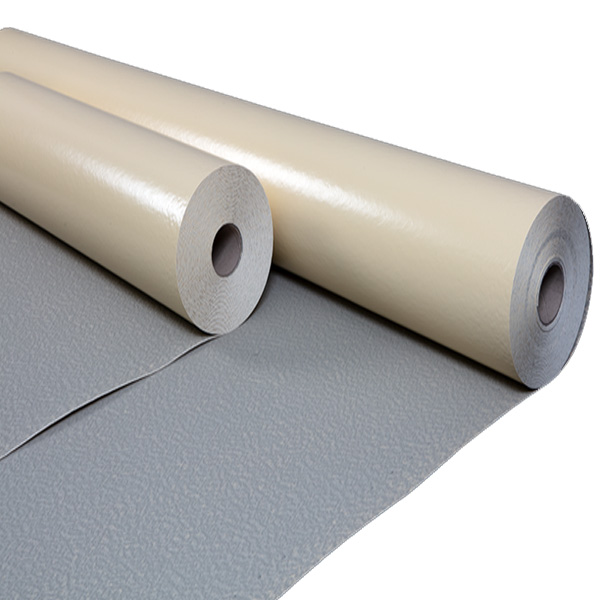

Aritex offers strong puncture resistance thanks to its uniform thickness and optional smooth or textured surfaces. In reservoirs and landfills, puncture resistance is crucial for long-term operational stability.

With high mechanical strength limits, Aritex HDPE waterproofing membrane meets requirements ranging from uneven foundations to high hydrostatic pressure environments.

HDPE’s low thermal expansion minimizes shrinkage in areas with large temperature fluctuations. With high elongation capacity, Aritex avoids cracking at stress points, making it suitable for soft or settling soil conditions.

This contributes greatly to the membrane’s reliability in infrastructure that requires long-term stability.

The material resists alkalis, acids, and organic compounds well. In wastewater treatment systems, Aritex HDPE waterproofing membrane maintains structural protection and stability.

With its extremely low permeability coefficient, the membrane minimizes leakage and ensures consistent operating conditions.

To select the right membrane, contractors often compare Aritex HDPE waterproofing membrane with well-known brands like Huitex, Solmax, and HSE. The comparisons below highlight their differences.

Both Aritex and Huitex are stable products, but Aritex offers advantages in price and uniform polymer structure. In landscape ponds and aquaculture systems, Aritex provides less shrinkage and is easier to install.

Solmax excels in mechanical durability and global certifications, suitable for large-scale projects. However, Aritex HDPE waterproofing membrane has better pricing and strong UV durability, making it cost-effective in the Vietnamese market.

HSE covers surfaces well but has lower puncture resistance. In reality, Aritex is preferred in rocky foundations or projects requiring higher durability.

Thickness determines performance and lifespan. Selecting the right thickness ensures safety and optimizes project cost.

Shrimp ponds, koi ponds, and landscape lakes typically use 0.5–1.0 mm. For intensive aquaculture with higher loads, 1.0–1.5 mm is recommended.

Basements and technical pits require high tensile strength, so 1.5 mm and above are preferred to prevent cracking and groundwater pressure issues.

For landfills, reservoirs, or wastewater treatment ponds, 1.5–2.0 mm is necessary for long-term waterproofing and puncture resistance.

The market price of Aritex HDPE waterproofing membrane is relatively stable and primarily varies by thickness and roll specifications. The most commonly quoted thicknesses are 0.5–1.0 mm, while thicker materials such as 1.5 mm and 2.0 mm are referenced based on the general HDPE market.

Price reference per m²:

In general, price increases progressively with thickness, and cost variation becomes larger beyond 1 mm.

Buying full rolls is cheaper than buying by square meter due to lower waste and fewer seams.

Reference pricing:

Reasons for the price gap include cutting labor, inventory handling, increased seam quantity, and material waste. For projects over 5,000–10,000 m², roll purchase is the most cost-effective option.

Despite fluctuations, Aritex HDPE waterproofing membrane remains one of the most cost-efficient options in its category.

In most projects, material cost only accounts for 40–60% of the total budget. The rest comes from installation, welding, and inspection.

Large-scale projects have lower installation costs due to easier deployment. Double seam welding is preferred in high-risk projects such as landfills and wastewater ponds.

This ensures the Aritex HDPE waterproofing system operates safely throughout its lifespan.

With proper installation, Aritex HDPE waterproofing membrane can last 20–25 years.

Check thickness, surface uniformity, product labels, and batch numbers. Textured membranes should have consistent texture.

Labels must show thickness, technical specifications, ASTM standards, and batch codes. Request CO/CQ to ensure authenticity.

Choose suppliers with technical experience, proper welding equipment, and verified certifications to ensure longevity and performance.

All shipments include CO/CQ and comply with ASTM and ISO standards.

Experienced teams handle aquaculture ponds, landscape lakes, and wastewater systems.

Transparent pricing and tailored warranty policies are provided for each project.

For any details needing advice and support, customers please contact:

SKSUMO ĐÀ NẴNG WATERPROOFING COMPANY

Hotline: 083 999 0123

Website: https://sksumo.com/

Address: 586 Nguyễn Hữu Thọ, Cẩm Lệ, Đà Nẵng

SKSumo company headquarters on Google Maps

Yes. It meets the durability and chemical-resistance requirements of shrimp farming.

It typically lasts 15–25 years depending on thickness and UV exposure.

Yes. HDPE is more durable, more UV-resistant, and ages much slower than PVC.

Yes. Many Aritex HDPE membranes meet ASTM standards for sanitary landfills.

It depends on project needs. Aritex is cost-efficient, while Huitex has stronger global recognition. Both meet construction standards.