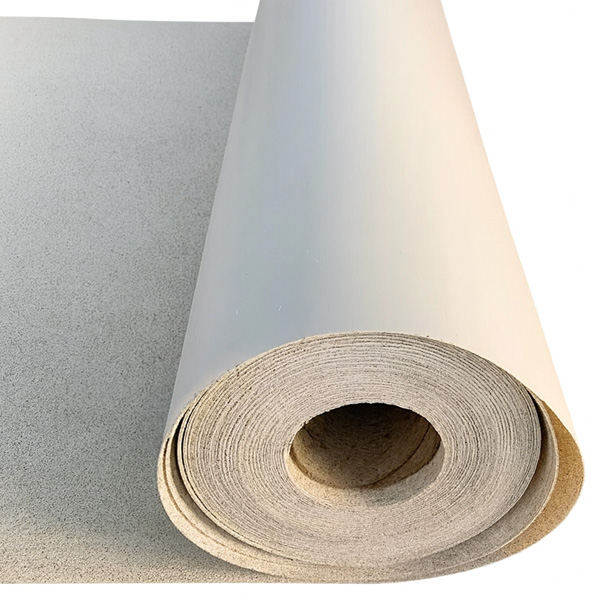

Choosing a waterproofing material requires a clear understanding of thickness, load-bearing capability, and associated standards. With growing interest in the 2mm hdpe waterproofing membrane, users need to know its functions, performance, and when it should be used to ensure construction safety.

.jpg)

In many waterproofing projects, users often struggle to select the appropriate thickness, especially when a project demands high durability. The appearance of the 2mm hdpe waterproofing membrane in shrimp ponds, reservoirs, landfills, or wastewater systems raises a common question: why use the 2mm type, and what is its purpose?

Each HDPE thickness is designed for a specific working level. The 2mm type is intended for structures under heavy loads, harsh environments, or requiring absolute waterproofing. This thickness enhances safety, reduces tearing risks, and ensures long-term durability under real operating conditions.

Understanding what a 2mm hdpe waterproofing membrane is used for helps users avoid buying the wrong material, installing it incorrectly, or choosing an unsuitable thickness that could lead to high repair costs later.

A 2mm membrane is not simply “thicker”; it delivers significantly superior technical specifications compared to 1mm or 1.5mm membranes. This is why the 2mm hdpe waterproofing membrane is prioritized for heavy-load areas, chemical exposure, or locations with prolonged sunlight.

One of the most important factors is load-bearing capacity. The 2mm membrane has high tensile strength and minimizes tearing risks when placed on uneven ground or under high water pressure. The material is also more stable against heat, expansion, and vibration, helping it maintain surface form over time.

Its UV resistance is also superior. With proper carbon black content, the membrane can withstand long-term sunlight exposure without rapid aging-particularly important for shrimp ponds, landscape ponds, or areas where the membrane surface is not covered with soil.

Additionally, the 2mm thickness provides an extremely low permeability rate-almost zero when welded correctly. This is crucial for landfills, chemical ponds, or wastewater systems where environmental safety is a top priority.

Finally, durability. Thanks to its thicker, more stable structure, a 2mm hdpe waterproofing membrane can last 20–50 years depending on conditions. This is why major projects often select the 2mm type from the start to minimize technical risks and reduce maintenance costs.

Many high-safety projects prioritize the 2mm hdpe waterproofing membrane, not due to “market trends,” but because of proven technical advantages. This thickness is considered a benchmark for heavy-load projects and long-term exposure to water, chemicals, or outdoor UV. Below is a detailed breakdown of performance factors.

Under the same installation conditions, a 1mm membrane is easily stretched or torn at the edges under high water pressure or when installed on uneven soil. The 1.5mm type is slightly more durable but still insufficient for large-scale, high-load projects. In contrast, the 2mm membrane delivers higher tensile strength, elongation, and puncture resistance, significantly reducing failure risks over time. Reservoirs, engineered landfills, and waste treatment pits often require the 2mm type for these reasons.

A standout advantage of the 2mm hdpe waterproofing membrane is its extremely low permeability, minimizing leakage through the membrane surface. When welded correctly, double-seam welding forms a continuous barrier, preventing fluid penetration even under increasing pressure-crucial for wastewater systems and chemical ponds.

Outdoor temperature changes cause expansion and contraction cycles. Thinner membranes age faster or develop surface cracks, while the 2mm type maintains good flexibility without becoming brittle in sudden temperature shifts. Its carbon black composition allows it to endure 8–12 sunlight hours per day while maintaining performance-ideal for shrimp ponds, landscape ponds, and open reservoirs.

In environments containing industrial wastewater, fertilizers, acids, or mild alkalis, the membrane must retain structural integrity. The 2mm thickness adds extra protection, reducing chemical degradation and increasing service life-hence its use in farms, factories, and waste-treatment sites.

Its performance makes the 2mm hdpe waterproofing membrane the top choice for:

A lesser-noted advantage: the 2mm membrane is heavier and adheres better to the ground, preventing wind uplift unlike thinner types. This speeds up installation and reduces surface slippage-especially on slopes or soft soil.

Using the 2mm type reduces repair costs, inspection frequency, and operational risks throughout the membrane’s lifespan-key benefits for investors.

Projects using the 2mm hdpe waterproofing membrane for many years show stable performance and extremely low failure rates. This comes from its superior tensile strength, elongation, and puncture resistance. Under high water pressure or continuous chemical exposure, the membrane maintains structural stability without deformation.

A major benefit is outdoor durability. In intense sunlight and fluctuating temperatures, the 2mm membrane retains flexibility and does not crack-especially in uncovered applications like shrimp ponds or landscape ponds.

Its near-absolute leak resistance is a core strength. Combined with double-seam welding, wastewater and chemical containment systems achieve high environmental safety.

Regarding lifespan, most 2mm installations last 20–50 years depending on operation conditions. This long-term stability reduces maintenance costs and increases investment efficiency.

Because of this performance, many contractors no longer use multiple material layers-one certified 2mm HDPE layer is sufficient. This simplifies construction, shortens installation time, and reduces technical errors.

For deep ponds, fluctuating water levels, or long-term operation, the 2mm type is best. It resists bottom tearing, puncturing, and compression from aeration systems.

For high-risk waste, 1.5mm is often unsafe. The 2mm type offers better containment, resists leachate corrosion, and meets many regional standards.

These require absolute stability. The 2mm membrane provides superior waterproofing, compression resistance, and thermal stability.

Chemical exposure demands strong protection. The 2mm type maintains structural stability and prevents corrosion-related failures.

Biogas systems contain corrosive organic waste. The 2mm type prevents leakage and maintains durability in long-term operation.

Where groundwater control or soil separation is needed, the 2mm membrane offers better stability and reduced long-term deformation.

Overall, the 2mm type fits any project requiring high safety, long service life, and low failure risk. Choosing the right scenario helps optimize costs and ensure stable operation.

Selecting a 2mm hdpe waterproofing membrane requires ensuring it meets quality standards. Large projects often require GM13 or equivalent standards regarding tensile strength, thickness, UV resistance, and permeability.

Welding technique is crucial. Double-seam welding must be used to create two parallel welds for maximum safety. After welding, technicians must test seams using air pressure or water to ensure full sealing-mandatory for reservoirs and landfills.

Ground preparation is equally important. The base must be free of sharp objects, leveled, and compacted to avoid membrane damage during operation. On slopes, edges must be anchored securely to prevent slipping or stretching.

Material storage matters as well. Membranes should be covered before installation and kept away from sharp objects.

With proper standards and installation procedures, a 2mm hdpe waterproofing membrane delivers maximum performance and long-term operational stability.

The 2mm hdpe waterproofing membrane is an optimal choice for heavy-load structures, harsh environments, or long-term durability requirements. It provides high performance, near-absolute waterproofing, and excellent lifespan when installed correctly. Choosing the right thickness based on project type, load, and operating conditions ensures accurate decision-making and long-term cost savings.

Yes, if the pond is deep or used for many years. For small ponds with low mechanical impact, thinner types may work, but 2mm offers higher safety and lower maintenance.

Because of its excellent waterproofing, puncture resistance, and chemical resistance. The environment is highly corrosive, so 2mm ensures long-term safety.

When the project faces heavy loads, high water pressure, or requires longer lifespan. Outdoor reservoirs, deep ponds, and waste-treatment sites typically require 2mm.

Yes. The 2mm thickness prevents gas leakage, resists corrosion, and maintains durability during long-term exposure to organic waste.

Prepare a clean, flat base, remove sharp objects, use proper double-seam welding, and test the seams before acceptance to ensure maximum performance and safety.