The demand for floor waterproofing continues to increase as modern structures require high durability and minimized risks of reverse seepage. Many investors are considering HDPE membranes as a professional solution, but the actual effectiveness of using them for floors is still a question that needs deeper evaluation.

When choosing a waterproofing solution for floors, users often consider load capacity, durability, and long-term stability. HDPE waterproofing membranes become a notable option due to their advantages in lifespan, chemical resistance, and tensile strength. However, several factors make users want to understand actual performance before deciding to apply the hdpe waterproofing membrane installation method.

Basement floors, roof decks, technical floors, water treatment areas, and structures exposed to prolonged moisture are at high risk of water infiltration. When water penetrates the floor, concrete may lose strength, allowing cracks, spalling, and reinforcement corrosion. Therefore, the waterproofing material must ensure complete water blocking, stability under pressure, and resistance to environmental damage.

Floors are easily affected by capillary action, thermal cracks, concrete voids, inconsistent joint transitions, or construction errors. Additionally, areas exposed to chemicals require long-lasting resistance. HDPE meets many of these requirements but must be installed correctly to avoid blistering and delamination.

When considering HDPE membranes for floors, users should examine key criteria that determine waterproofing effectiveness. Each technical parameter affects long-term durability and the stability of performance after applying the hdpe waterproofing membrane installation method.

HDPE commonly ranges from 0.5-2.0 mm; 1.5-2.0 mm is preferred for floors due to higher puncture resistance. Areas with mechanical equipment or heavy traffic require greater thickness to reduce tearing risks. Higher mechanical strength ensures better waterproofing performance, especially in zones with concentrated loads.

HDPE has extremely low water permeability and excellent sealing, suitable for humid environments or exposure to industrial chemicals. In wastewater treatment or solvent storage areas, HDPE offers exceptional resistance, making it widely used in high-durability technical applications.

Installation on a flat surface requires the material to minimize shrinkage and avoid trapping air. If the floor does not allow proper vapor escape, heat may cause the membrane to blister. Therefore, HDPE must be properly anchored at edges, corners, and wall-floor transitions for secure indirect adhesion.

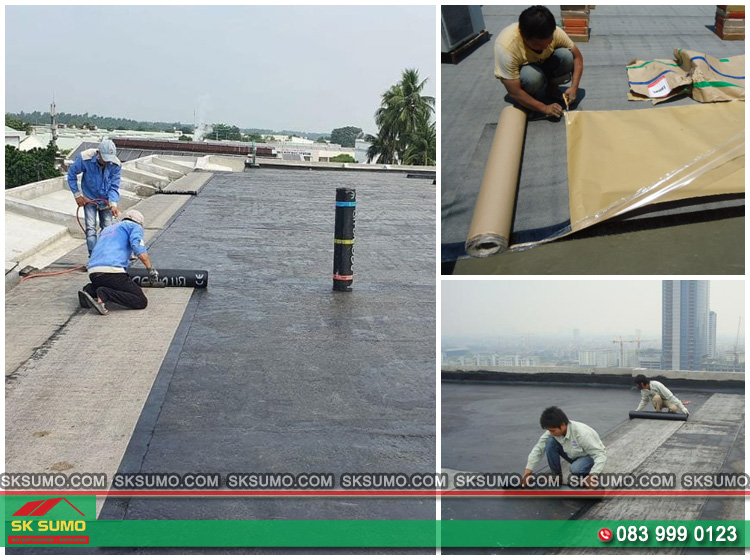

One of the key factors determining the effectiveness of the hdpe waterproofing membrane installation method is adherence to the correct installation procedure. Each step-from surface preparation to seam inspection-directly affects final quality. HDPE demands higher technical precision compared to coating-type waterproofing materials.

The surface must be clean, flat, and free of debris. Large cracks must be repaired with polymer mortar to create a smooth surface. Wall bases should be coved to reduce tension on the membrane. Careful preparation increases stability during laying and heat welding.

HDPE membranes are laid from the lowest point to ensure proper overlap direction. Sheets must overlap at least 10-15 cm to avoid gaps. On large floors, water bags or temporary bars help keep sheets from shifting during welding. Proper layout reduces installation time and prevents errors.

This is the most critical step. Welding temperature must be stable-not too high to burn the membrane, nor too low to reduce adhesion. Seams are tested using air-pressure methods or specialized tools to ensure complete sealing. At intersections or corners, extrusion welding is used to form high-strength seams.

After completion, the membrane must be protected with cement boards, wooden sheets, or mortar layers to prevent punctures. During MEP work and interior finishing, maintaining membrane protection is essential to preserve sealing and long-term durability.

To fully assess the hdpe waterproofing membrane installation method, it is important to recognize its strengths and limitations. HDPE offers long-term value but performs optimally only when applied in the right conditions.

HDPE has high tensile strength, near-zero water permeability, excellent chemical resistance, and a lifespan exceeding 20 years. It withstands mechanical impact, heat, and UV exposure, suitable for both civil and industrial structures. Its protection against chemical corrosion helps reduce long-term maintenance costs.

HDPE is vulnerable to punctures from sharp objects without proper protection. Installation is more complex than coating materials and requires skilled workers. If the surface lacks proper vapor escape treatment, blistering may occur and reduce waterproofing efficiency.

Typical issues include insufficient welding heat, inadequate overlap, dusty or uneven surfaces, improperly handled corners, or poor membrane protection. These errors may cause seepage even after project handover.

To determine the suitability of the hdpe waterproofing membrane installation method, it is essential to identify which floor types benefit most from HDPE. Each structure has different load, environmental, and moisture conditions, so choosing the right scenario reduces costs and increases durability.

These are the most suitable applications. Basements face continuous reverse water pressure from the soil. In confined and humid conditions, HDPE offers superior waterproofing, creating an almost absolute barrier. However, thicker membranes and robust mechanical protection are required.

Roof decks face major temperature fluctuations and UV exposure, which degrade many waterproofing materials. HDPE has good UV resistance but requires optimal drainage to prevent blistering from heat buildup. Areas with high technical equipment density must use thick protective boards.

In chemical handling areas, HDPE stands out with resistance to acids, alkalis, and solvents. Wastewater treatment systems, industrial plants, or chemical-exposed factory floors use HDPE to extend structural lifespan and reduce maintenance costs.

Beyond technical considerations, evaluating acceptance standards, costs, and compatibility between material and operating conditions is necessary before applying the hdpe waterproofing membrane installation method. These factors help investors make informed decisions.

International standards such as ASTM D4437 and ASTM D6693 evaluate seam quality and tensile strength. Compliance ensures complete sealing, preventing leakage during use. Acceptance documents must include seam inspection reports, as-built drawings, and construction logs.

HDPE installation cost depends on membrane thickness, area, and floor complexity. A 1.0 mm membrane suits low-load floors, while 1.5-2.0 mm types are required for basements and high-load areas. Costs may increase where many corners, wall bases, or penetrations require special treatment.

Thickness should match usage conditions and risk level. Floors subject to constant water pressure or mechanical abrasion should use thicker membranes. Technical floors require high mechanical strength and stable chemical resistance.

Comparisons help contractors and investors clearly understand the relative advantages of the hdpe waterproofing membrane installation method versus other common solutions. Each material has strengths, but HDPE excels in harsh environments.

PVC is easier to install and more flexible in tight corners, but less durable against chemicals and UV. For long-lifespan projects or harsh conditions, HDPE is preferred.

Coatings are suitable for small projects and quick application but do not perform well under strong water pressure. HDPE offers superior durability and absolute waterproofing, especially for basements and technical floors.

Some projects require greater protection to maintain structural durability. These may combine the hdpe waterproofing membrane installation method with additional layers for enhanced safety.

Protection layers such as wooden boards, cement boards, PVC sheets, or mortar coating prevent mechanical impact during construction. Proper protection maintains HDPE stability and minimizes puncture risks.

In environments with aggressive chemicals or high pressure, HDPE can be combined with epoxy coatings or spray-applied membranes for maximum safety. This is commonly applied in industrial plants and chemical treatment areas.

HDPE is a highly durable waterproofing material suitable for floors exposed to water or harsh environments. The effectiveness of the hdpe waterproofing membrane installation method largely depends on proper installation techniques and protective layers. For projects requiring long lifespan or absolute waterproofing, HDPE is a reliable choice. Investors should assess floor type, load, and environmental conditions to select suitable thickness and installation methods.

Yes, but drainage must be optimized and a mechanical protection layer added to reduce blistering and damage during use.

HDPE has high chemical resistance, suitable for areas containing solvents, acids, or industrial wastewater.

1.5-2.0 mm is recommended for puncture resistance and stability under reverse water pressure.

Yes. Heat welding, corner detailing, and seam testing require experienced technicians to ensure complete sealing.

Absolutely. In harsh environments, combining materials enhances durability and extends floor lifespan.