During the estimating process, the cost of waterproofing materials is always an important factor. The price list of self-adhesive hdpe waterproofing membranes below provides clear information for each category, helping you easily compare prices and choose an optimal investment level while ensuring project quality.

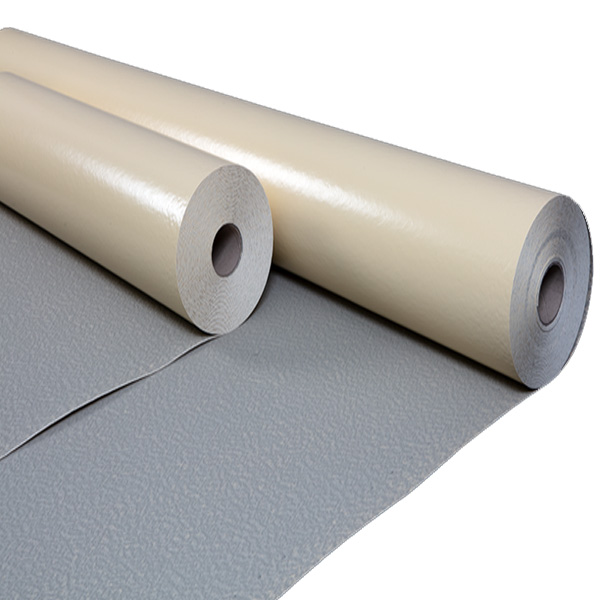

A self-adhesive HDPE waterproofing membrane is a polymer material constructed from high-density polyethylene combined with a specialized adhesive layer on the underside to ensure strong bonding to concrete surfaces. This material performs highly in construction works thanks to its water resistance, chemical resistance, and excellent tensile strength.

For categories requiring complete waterproofing, self-adhesive HDPE membranes are considered a more modern option compared to emulsion bitumen or traditional cement-based waterproofing coatings. When users are concerned about hdpe waterproofing membrane prices, understanding the structure helps evaluate the correct membrane type.

The self-adhesive HDPE membrane creates a fully waterproof layer, offers instant adhesion, and reduces the risk of peeling during project operation. This material withstands thermal expansion, resists tearing caused by small structural movements, and maintains tight sealing when installed correctly.

Compared to traditional waterproofing materials, it provides more stable waterproofing performance and long service life. Thanks to these benefits, demand for hdpe waterproofing membrane price information continues to increase in residential and industrial construction.

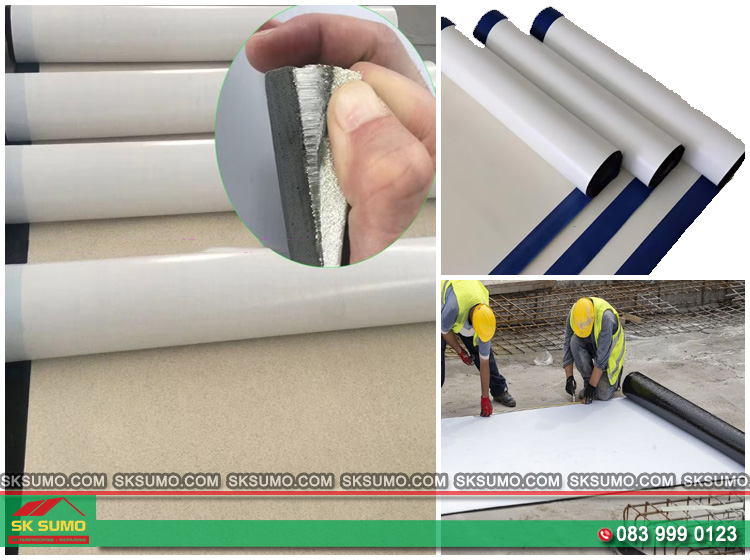

Self-adhesive HDPE membranes protect concrete structures from groundwater, rainwater, and hydrostatic pressure. The material is commonly installed in locations such as wall bases, foundation bottoms, retaining walls, basements, roofs, and technical floors.

In new constructions, self-adhesive HDPE membranes shorten installation time, reduce long-term maintenance costs, and increase overall durability. Therefore, information related to hdpe waterproofing membrane prices becomes crucial in construction budgeting.

Thickness is the major factor influencing hdpe waterproofing membrane prices. The thicker the membrane, the more material is used, the stronger the load resistance, and the higher the price. Common thicknesses include 0.5mm, 1mm, 1.5mm, and 2mm, suitable for different technical requirements in construction.

The higher the density, the more durable the membrane and the greater its weight. Types that use virgin HDPE generally cost more due to better thermal and mechanical stability. In quotations, standard weight is a parameter verified under ASTM standards and directly affects hdpe waterproofing membrane pricing.

The adhesive layer determines bonding strength to the concrete substrate. High-quality adhesives allow fast installation, fewer edge-peeling issues, and better resistance to reverse seepage. Therefore, products with premium adhesive layers are more expensive than those using rosin-based or softening-type adhesives.

Membranes with high tensile strength can withstand mechanical impact during backfilling or project operation. Puncture resistance helps prevent damage under pressure from sharp objects or soil movement. The higher these values, the higher the hdpe waterproofing membrane price.

High-quality HDPE membranes feature surface structures that allow thermal welding or self-adhesion to reach maximum tightness. This reduces the risk of reverse seepage and increases project longevity. Materials with superior tightness belong to higher price segments.

Products that meet ASTM D5199, ASTM D6693, or ISO 9001 standards generally cost more due to strict certification requirements. These standards ensure stable quality and increase reliability for projects with demanding technical specifications.

The difference between imported products and domestic products creates a significant price gap in hdpe waterproofing membranes. Reputable brands such as Solmax, GSE, or major domestic factories always have higher prices than unverified or uncertified materials.

|

Product type |

Reference price (VND/m²) |

|---|---|

|

1.2mm GPS HDPE membrane |

~145,000 |

|

1.5mm GPS HDPE membrane |

~200,000 |

|

1.2mm Fosroc HDPE membrane |

~145,000 |

|

1.5mm Fosroc HDPE membrane |

~200,000 |

|

1.2mm Sika HDPE membrane |

~145,000 |

|

1.5mm Sika HDPE membrane |

~200,000 |

|

1.2mm Visco HDPE membrane |

~145,000 |

|

1.5mm Visco HDPE membrane |

~200,000 |

Note: Prices exclude VAT, quantity-based discounts, and installation costs.

For detailed consultation and to receive the best hdpe waterproofing membrane quotation, please contact:

SKSUMO WATERPROOFING COMPANY

Hotline: 083 999 0123

Website: https://sksumo.com/

Address: 586 Nguyễn Hữu Thọ, Cẩm Lệ, Đà Nẵng

Head office of SKSumo on Google Maps

When researching hdpe waterproofing membrane prices, users often ask whether this material is truly more optimal than traditional options such as self-adhesive bitumen, PVC, or waterproofing coatings. Comparing these options correctly helps choose the most effective material and optimize costs.

In many residential projects, self-adhesive bitumen is a popular choice due to its low initial cost. However, in the long run, HDPE delivers more stable waterproofing, especially in areas with water pressure or structural movement.

From a project-operation perspective, initial HDPE investment is higher, but maintenance costs are significantly lower. Therefore, in terms of life-cycle cost, hdpe waterproofing membrane prices are more efficient.

PVC has good elasticity and is easy to install on flat surfaces. However, self-adhesive HDPE offers better mechanical durability, chemical resistance, and resistance to soil pressure.

This difference makes hdpe waterproofing membrane prices higher than PVC, but with more stable quality from residential to industrial works.

Waterproofing paint is a low-cost solution but heavily depends on workmanship and surface quality. Under prolonged moisture or small surface cracks, paint layers often fail.

Meanwhile, HDPE is an independent physical barrier, providing active waterproofing unaffected by moisture.

Therefore, for important categories such as foundations and basements, hdpe waterproofing membrane prices are higher but offer superior long-term protection.

Small projects such as townhouses, villas, or auxiliary structures usually require moderate waterproofing. Users should select thicknesses from 0.5mm to 1mm to balance cost and performance.

For this group, hdpe waterproofing membrane prices are low and suitable for most residential needs.

High-rise buildings carry larger loads and are strongly affected by groundwater. Membranes from 1mm to 1.5mm with high tensile strength and puncture resistance are needed.

This group has higher hdpe waterproofing membrane prices due to stringent technical requirements and large quantities.

Structures such as manholes, technical tanks, pump rooms, or reservoirs require high safety and absolute waterproofing. Thicknesses from 1.5mm to 2mm are suitable.

Because of these requirements, this segment always has the highest hdpe waterproofing membrane prices.

Some projects select thinner membranes to save costs but end up requiring repairs or replacement shortly after. Conversely, choosing excessive thickness for light categories causes unnecessary waste.

Mistake in installing self-adhesive membranes leading to edge peeling and reverse seepage

If the surface is not properly cleaned, dried, and leveled, the adhesive layer cannot bond evenly. Edge peeling allows water to seep backward into the structure, reducing lifespan.

Membranes must be stored in cool, shaded areas, away from direct sunlight and strong impact. Even small cuts can affect tightness after installation.

SKSumo provides quotations based on actual technical standards instead of generic price levels. Users receive complete information about thickness, weight, brand, and optimal installation methods.

The pricing process is based on drawings, material quantities, and certification requirements. This ensures accurate estimates and appropriate costs for each project.

Consultants recommend suitable thickness based on load, water pressure, and soil conditions. This prevents incorrect selection and saves costs while ensuring waterproofing performance.

Each project has its own standards. SKSumo ensures materials meet necessary certifications and suit each requirement for safety, durability, and lifespan.

Material and labor costs are listed separately with clear descriptions for each category. This ensures transparency and avoids unnecessary extra costs.

For large projects, SKSumo offers volume-based discounts and supply-schedule incentives. This significantly reduces total cost while maintaining material quality.

In summary, understanding the price levels for each type of HDPE membrane helps you build a more effective cost plan. Choosing the right material not only saves budget but also enhances durability and safety for all construction categories.

No. The surface must be clean, dry, and flat for the adhesive to bond tightly and prevent early edge peeling.

Yes. The greater the thickness, the higher the price due to more material usage and higher certification requirements.

Yes, if using 1.5mm thickness or higher. Thinner types are more vulnerable to puncture or water loss under high pressure.

Depends on the product. Some high-grade self-adhesive lines do not require primer, but most should still use it for optimal adhesion.

Mainly thickness, adhesive-layer quality, and level of protection from mechanical impact during backfilling.