Durability and adaptability to the operating environment are key factors when selecting waterproofing membranes for landscape ponds, aquaculture systems, and landfills. HDPE Huitex and HSE share many similarities but differ significantly in UV stability, elongation, and puncture resistance. A detailed comparison helps users accurately evaluate which material is best suited.

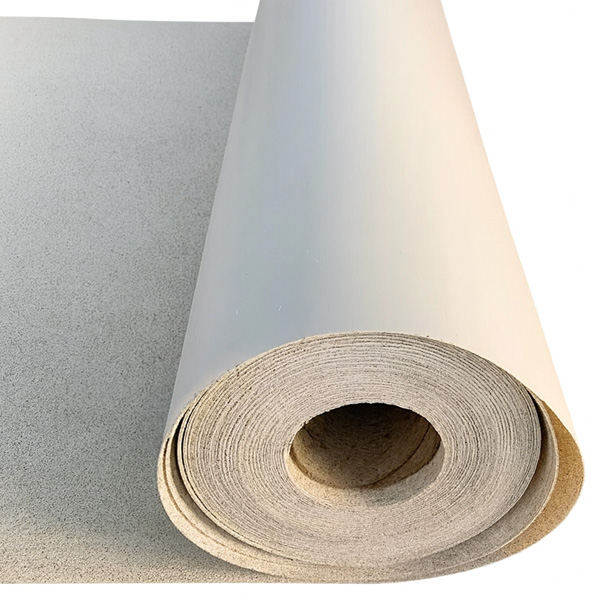

The Huitex HDPE waterproofing membrane is known as a geomembrane line that meets ASTM international standards, manufactured on Taiwanese production lines with high stability and superior lifespan. Compared with HSE, both belong to the HDPE geomembrane group but differ in extrusion technology, surface structure, and polymer particle uniformity. Users need to understand these characteristics to select materials appropriate for each project, especially landscape ponds, high-tech aquaculture systems, and landfills.

The Huitex HDPE waterproofing membrane is made from high-density virgin HDPE combined with UV-stabilizing additives that enhance anti-aging performance under direct sunlight. Its structure includes long-chain polymer layers that provide high tensile strength while maintaining good elongation to withstand soil movement. With evenly distributed carbon black additives, Huitex delivers outstanding durability in outdoor projects, biological ponds, and saline environments with high corrosiveness.

HSE also uses virgin HDPE, but the carbon black ratio and UV stabilizers are controlled according to the Chinese manufacturer’s standards. The material provides good tensile strength but lower elongation than Huitex. This makes HSE suitable for stable-base projects with minimal deformation, but not as optimal as Huitex in weak-soil areas or structures exposed to large thermal fluctuations.

Huitex uses a uniform three-layer co-extrusion technology, resulting in high flatness, minimal thickness deviation, and reduced risk of tearing on large surfaces. HSE commonly uses two-layer extrusion, which causes greater thickness variation, making it suitable for lower-budget projects. Understanding these differences helps users make accurate decisions when selecting Huitex HDPE waterproofing membranes or HSE materials.

To evaluate the quality of the Huitex HDPE waterproofing membrane, ASTM standards related to tensile strength, elongation, UV resistance, and puncture resistance must be considered. These parameters are essential for predicting lifespan and construction safety.

Huitex achieves higher tensile strength thanks to its pure polymer and uniform carbon black dispersion. Its elongation remains within a safe range for structures subjected to tensile loads during welding and installation. HSE has good tensile strength but lower elongation, making it more prone to tearing under sudden tensile forces or soil deformation. For projects requiring high precision, Huitex provides more stable performance.

UV resistance is a key factor helping the Huitex HDPE waterproofing membrane maintain long outdoor lifespan. Huitex incorporates next-generation UV stabilizers that limit aging and cracking over time. HSE also resists UV radiation but degrades faster under continuous exposure. Therefore, Huitex is more suitable for Central Vietnam’s intense sunlight and wide thermal fluctuations.

Huitex is tested according to ASTM D5322, offering excellent chemical resistance in wastewater, mild acids, and saltwater. This is why it is widely used in shrimp ponds and coastal biological ponds. HSE can tolerate chemicals but requires closer monitoring because polymer degradation occurs faster.

Huitex demonstrates high puncture resistance due to uniform membrane structure. When installed over gravel, roots, or uneven surfaces, it performs reliably. HSE also resists puncturing but loses strength at points where thickness is inconsistent. For large-scale or high-safety projects, Huitex offers more dependable performance.

In practice, the durability of the Huitex HDPE waterproofing membrane depends heavily on environmental conditions. When compared with HSE, their differences become evident in harsh settings.

Huitex has a smooth, uniform surface that minimizes blistering caused by sunlight and microbial activity. It offers a lifespan of 15 to 25 years. HSE performs adequately but tends to fade and lose elasticity faster, typically within 5 to 10 years.

High-tech shrimp farming requires membranes that withstand microbial load, saltwater, and chemicals. The Huitex HDPE waterproofing membrane performs well due to its salt resistance and stable surface. HSE can be used but requires more frequent monitoring and earlier replacement.

Landfills and treatment ponds require membranes with strong puncture resistance and chemical tolerance. Huitex meets strict ASTM D5322 standards, ensuring long-term reliability. HSE meets basic requirements but degrades faster in acidic environments.

Central Vietnam experiences high temperatures, strong winds, and high humidity. This is an ideal environment to assess the performance of the Huitex HDPE waterproofing membrane. Huitex typically lasts 20 to 30 years with low aging rates, while HSE usually lasts 12 to 18 years depending on operating conditions.

Cost is a critical factor in material selection. Although more expensive, the Huitex HDPE waterproofing membrane offers better long-term value due to outstanding durability and reduced maintenance risks.

Huitex is generally 10 to 20 percent more expensive than HSE depending on thickness, mainly due to international-standard production processes and high-quality UV additives. For projects requiring lifespan above 15 years, Huitex offers better investment efficiency.

Huitex has consistent thickness with minimal variation, ensuring stable pricing and reduced installation waste. HSE offers lower prices but requires careful inspection of actual thickness to avoid deviations during acceptance.

Prices depend on polymer origin, carbon black ratio, and testing standards. Huitex uses high-purity polymer, resulting in a higher price but better durability. HSE is more economical but has lower mechanical strength and lifespan.

Although initial costs are higher, the Huitex HDPE waterproofing membrane yields lower lifetime costs due to fewer repairs and longer durability. HSE suits low-budget projects but carries higher maintenance risks.

In real construction settings, choosing the Huitex HDPE waterproofing membrane or HSE depends not only on durability but also on weld quality, surface flatness, and acceptance requirements. Installation quality plays a decisive role in long-term performance.

To achieve optimal impermeability, the subgrade must be leveled, cleaned of sharp objects, and compacted to a safe CBR level. The smoother the surface, the better the installation quality, especially with the Huitex HDPE waterproofing membrane, whose elasticity and uniformity enhance performance. HSE requires stricter surface preparation to avoid puncturing.

Huitex allows more stable welding due to its uniform surface, producing wider and more consistent seams. HSE can also be welded but requires stricter temperature control. The standard welding process includes machine testing, dual-track welding, and vacuum testing. Huitex offers a higher ASTM-compliant welding success rate.

Common issues include insufficient heat, overheating, inadequate seam overlap, and tearing due to uneven subgrade. A proper checklist includes monitoring ambient temperature, calibrating welding speed, testing seams before each shift, and verifying protective layers. The Huitex HDPE waterproofing membrane shows better thermal stability, reducing welding errors under strong sunlight.

Acceptance follows ASTM D4437, including visual inspection, thickness measurement, seam tensile tests, and vacuum testing. Large projects such as shrimp farms and landfills require complete documentation. The Huitex HDPE waterproofing membrane simplifies acceptance due to internationally certified testing.

Material selection depends on foundation stability, chemical exposure, UV intensity, and desired lifespan. In many cases, the Huitex HDPE waterproofing membrane is more advantageous.

Huitex provides a smooth surface with minimal wrinkles and thermal shrinkage, ideal for koi ponds, artificial lakes, and resort landscaping.

Saline and chemical environments require robust membranes. The Huitex HDPE waterproofing membrane performs stably under these conditions. HSE suits smaller operations but requires earlier replacement.

These settings demand high puncture resistance and chemical tolerance. Huitex meets strict standards, minimizing leachate leakage risks.

High UV and thermal variation favor Huitex due to superior UV stabilization. HSE can be used but may require thicker gauges.

Projects using HDPE membranes from SKSumo Da Nang benefit from verified material origin, trained installation teams, and long-term maintenance services.

SKSumo supplies officially imported Huitex products with complete certification and proper storage conditions that maintain the stability of the Huitex HDPE waterproofing membrane.

Technicians follow ASTM procedures, using automated welding machines and calibrated testing devices to enhance membrane performance.

SKSumo provides regular inspection services that detect risks early, reinforce seams, and monitor membrane aging, essential for large aquaculture and industrial projects.

The company evaluates technical requirements and budgets to recommend either Huitex or HSE. For long-lifespan projects, the Huitex HDPE waterproofing membrane is often the optimal choice.

Material choice should consider durability, budget, environmental conditions, and lifespan expectations. For most outdoor and chemically exposed projects, the Huitex HDPE waterproofing membrane strikes the best balance between durability and cost effectiveness.

Huitex suits projects requiring 15 to 30 years of lifespan. HSE suits short-term or low-budget work.

HSE is economical upfront, while Huitex minimizes long-term lifecycle costs.

With harsh UV and temperature variation, Central Vietnam projects benefit more from the Huitex HDPE waterproofing membrane.

In summary, Huitex is the safer choice if long-term durability, heat resistance, and saline environments are priorities. HSE is suitable when budget is limited and project conditions are less demanding. Accurately determining requirements ensures optimal investment and minimized maintenance risks.