Each project has its own waterproofing requirements, groundwater conditions, and budget. Comparing Solmax and Visco from the perspective of cost efficiency and durability helps engineers select the right material for applications ranging from residential projects to large-scale underground infrastructure.

In modern reinforced concrete structures, waterproofing requirements are increasingly strict as the structure must withstand high groundwater pressure, chemical exposure, and soil movement. Selecting the right waterproofing material not only affects construction quality but also determines operational lifespan.

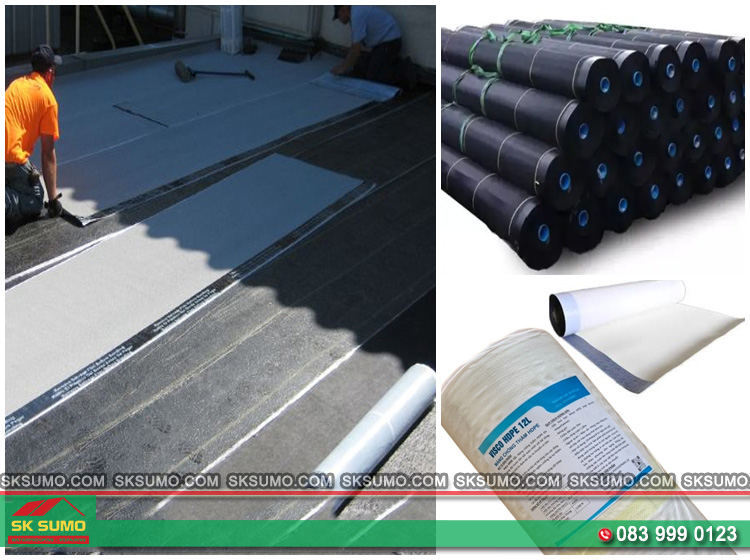

Among HDPE membrane materials, solmax hdpe waterproofing membranes and Visco HDPE membranes are two common choices, each suitable for different applications and performance levels. With absolute water resistance, high mechanical strength, and long service life, both materials are considered standard solutions for underground waterproofing systems.

Concrete inherently contains capillaries and shrinkage cracks that allow water to penetrate, causing steel oxidation and internal structural damage. Areas such as basements, raft foundations, elevator pits, and technical tanks often face high water pressure. Therefore, using solmax hdpe waterproofing membranes with absolute waterproofing capability has become a mandatory standard to protect the structure.

In multi-layer waterproofing systems, HDPE membranes function as the primary barrier that isolates water from concrete. With high tensile strength, chemical resistance, and near-zero permeability, this material is ideal for structures exposed to high groundwater pressure. Many large projects use solmax hdpe waterproofing membranes as the main waterproofing layer, combined with polymer-cement coatings and mechanical protection layers, creating a sealed system with more than 30 years of durability.

In the construction industry, solmax hdpe waterproofing membranes are highly regarded for material stability, superior tensile strength, and long service life under high water pressure. Solmax applies multi-layer blown-film extrusion technology that distributes antioxidants and carbon black evenly, reducing aging when exposed to chemicals or UV during pre-backfill stages.

Solmax HDPE geomembranes are made from virgin HDPE using blown-film extrusion technology, offering absolute waterproofing and high tensile strength for underground structures.

Solmax uses high-quality HDPE combined with thermal stabilizers and anti-aging additives to maintain flexibility over many years. Key properties include:

Solmax offers a wide range of thicknesses:

Among these, 1.2 mm and 1.5 mm are standard choices for basements, base slabs, and elevator pits. Options include smooth on both sides, one-side textured, or double-textured surfaces for steep slopes or vertical walls.

Solmax meets multiple well-recognized standards:

These certifications ensure suitability for underground works, technical tanks, and applications requiring high watertight performance.

In addition to solmax hdpe waterproofing membranes, Visco HDPE membranes provide a balanced option between quality and cost. Visco focuses on improving mechanical strength, thickness stability, and weldability, making it suitable for residential, commercial, and medium-to-high-demand infrastructure projects.

Visco uses virgin HDPE resin combined with stabilizing additives to maintain flexibility and prevent brittleness in concrete environments.

Key characteristics include:

Optimized production reduces thickness deviation and improves welding consistency.

Common thicknesses include:

Thicknesses of 1.2 mm and 1.5 mm are typically used for basements, elevator pits, and treatment tanks. Visco offers smooth or textured surfaces to improve friction with protection layers.

Visco is tested according to:

Test results show that Visco meets mechanical requirements for civil and commercial construction projects.

Comparing solmax hdpe waterproofing membranes and Visco helps engineers determine the most suitable material for each application. Each brand differs in additive formulas, material stability, and ASTM values.

|

Property |

Solmax |

Visco |

|---|---|---|

|

Tensile strength |

High |

High |

|

Elongation |

Very high |

Very high |

|

Puncture resistance |

Good |

Good |

|

Uniformity |

Stable |

Stable |

Each HDPE membrane delivers different levels of performance depending on its structure, thickness, and weldability.

For concrete structures requiring 30–50 years of service life, waterproofing materials must have high physical and chemical stability. Among HDPE membranes, solmax hdpe waterproofing membranes and Visco are two of the most widely used options. UV resistance, chemical resistance, and aging rate are key factors determining long-term performance.

UV resistance is the membrane’s ability to withstand degradation during sun exposure before backfilling.

Solmax contains a higher carbon black ratio and better thermal stabilizers, resulting in slower aging. Visco also has good UV stability but not as strong as Solmax, making it more suitable for projects with shorter exposure times.

Solmax is engineered to meet international standards for harsh chemical environments, including abnormal pH or corrosive substances. Visco performs well in residential wastewater or groundwater but is not as suitable as Solmax for industrial wastewater or high-chemical-concentration environments.

Solmax typically offers a design life of 30–50 years depending on thickness, while Visco averages 20–30 years. For deep foundations, elevator pits, technical tanks, or long-term infrastructure, Solmax is preferred due to superior mechanical and chemical stability.

In construction, material performance is only guaranteed when substrate preparation, membrane installation, and welding comply with standards. Engineers rate solmax hdpe waterproofing membranes as more stable in surface quality and weld consistency, reducing technical risks in underground structures.

Both membranes require smooth substrates free of sharp stones and debris. However, Solmax’s uniform structure and higher toughness reduce tearing risks during installation. With Visco, substrate inspection must be more meticulous to avoid stress concentration.

HDPE welding includes three main steps: edge preparation, machine setup, and air-pressure testing.

Solmax offers a wider thermal tolerance range, allowing stable welding under varying temperatures. Visco requires stricter control of welding temperature and travel speed to achieve quality welds. In large projects, Solmax significantly reduces welding errors.

Projects using Solmax are generally easier to inspect due to stable welds and fewer surface variations. Visco also meets requirements but needs more inspection points to avoid temperature- or thickness-related errors. Both are tested using air-pressure or vacuum methods, but Solmax tends to achieve higher pass rates.

Project decisions often consider not only material cost but also installation cost, service life, and repair risks. When comparing solmax hdpe waterproofing membranes and Visco, a long-term cost evaluation helps optimize the budget and avoid hidden expenses.

Solmax is about 10–20% more expensive than Visco depending on thickness and surface type. However, Solmax is commonly used in high-risk underground works, helping reduce future repair costs. Visco is more appropriate for medium-scale residential projects requiring budget optimization.

Solmax offers better surface stability, increasing construction speed and reducing welding defects-saving labor costs in large projects. Visco is still workable but requires more skilled technicians.

Solmax has lower life-cycle costs due to its long service life and superior aging resistance. Visco has lower initial cost but higher long-term cost if the project faces high water pressure or chemical exposure.

Engineers typically consider project type, groundwater conditions, loads, and maintenance requirements. Solmax hdpe waterproofing membranes are often preferred for critical or long-term projects, while Visco is suitable for medium-scale or cost-sensitive applications.

Solmax suits deep basements, elevator pits, large foundation slabs, technical tanks, or structures under high water pressure. Visco suits residential buildings, domestic water tanks, and medium-scale commercial works.

Solmax meets the GRI GM13 international standard, suitable for projects requiring strict certification. Visco meets basic ASTM standards for general construction needs.

If initial cost optimization is the priority, Visco is suitable. If the project demands long service life or low maintenance costs, Solmax offers better long-term economic efficiency.

⇒ Solmax ensures long-term performance for critical projects, while Visco suits medium-to-small projects requiring initial cost savings. Choosing the right HDPE membrane reduces backflow leakage risks and minimizes maintenance costs throughout the structure’s life cycle.

When the project requires long service life, high water pressure resistance, or stable weld performance.

When optimizing cost for medium-scale residential or commercial projects.

Yes, but the areas must be clearly defined according to technical requirements.

Tensile strength, elongation, material uniformity, and chemical resistance.