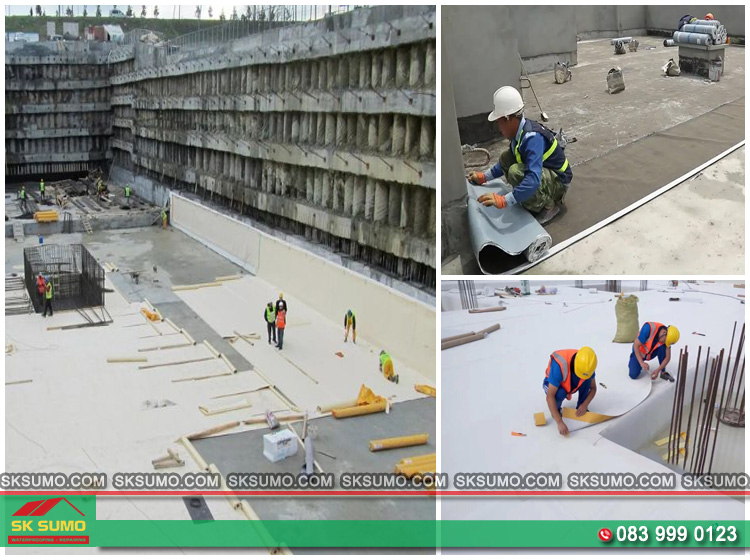

Many projects suffer leakage issues due to choosing the wrong hdpe waterproofing installation method, installing in strong winds, or failing to inspect weld seams. Experience from actual projects shows that assessing risks and standardizing the installation process from the beginning is the key factor determining long-term performance quality.

Based on real waterproofing projects in Đà Nẵng, SKSumo recognizes that hdpe waterproofing installation is a task that requires high precision, where even minor errors can directly affect durability and watertightness. Residential, infrastructure, reservoir, aquaculture pond, basement, landfill and wastewater treatment projects all require a strict installation process. We always follow ASTM and GRI GM13 standards and perform all necessary inspections to ensure the membrane remains stable throughout its 20–40 year lifespan.

In a waterproofing system, the HDPE membrane is the final and most important protective layer. During hdpe waterproofing installation, SKSumo optimizes impermeability, tear resistance and backflow prevention by strictly controlling every weld seam. Certified materials help reduce operational risks and enhance environmental safety.

Structures requiring high watertightness such as shrimp ponds, fire-fighting reservoirs, landscape lakes, sanitary landfills, basements, or areas with strong groundwater pressure must apply hdpe waterproofing installation. SKSumo Đà Nẵng provides guidance on suitable membrane thickness, type and installation method for each technical condition to ensure long-term durability.

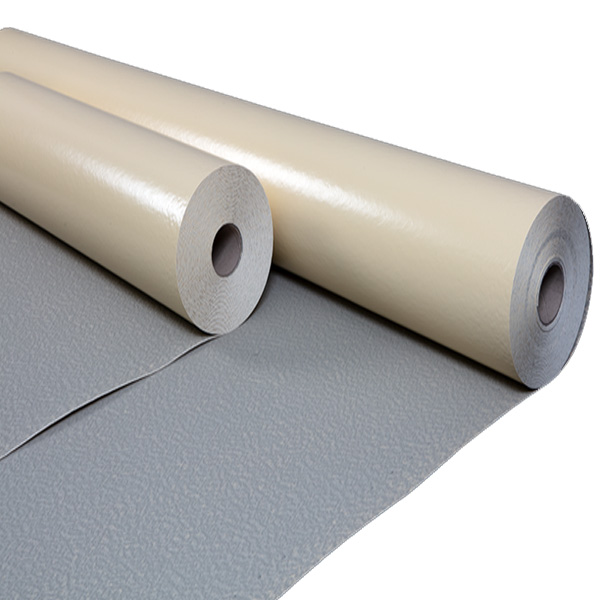

Each project has its own requirements for thickness. Normally, on the market, there are HDPE membranes with thicknesses from 0.5mm to 2.0mm, respectively:

Choosing the right thickness is an important step in the construction of hdpe waterproofing membranes. In particular, SKSumo specializes in providing self-adhesive HDPE waterproofing membranes specifically for residential construction projects.

SKSumo Đà Nẵng applies multiple hdpe waterproofing installation solutions depending on soil conditions, project requirements, and acceptance standards. Choosing the right solution increases lifespan, reduces maintenance costs and ensures operational stability. We consistently use standardized equipment, dual-track welding machines and certified technicians to guarantee accuracy for every project.

The soil must be compacted to standard, free of sharp rocks and covered with a protective layer. SKSumo strictly controls surface flatness before hdpe waterproofing installation to minimize wrinkles or membrane damage during operation.

Anchoring trenches are constructed to correct technical dimensions, ensuring edge stability when water levels fluctuate. Large reservoirs and landfill cells must apply this solution for long-term stability.

We use 300–500 g/m² geotextile in areas with high puncture risk. The protection layer increases system durability when performing hdpe waterproofing installation on uneven ground.

SKSumo has inspected many damaged projects caused by improper installation. During hdpe waterproofing installation, common errors such as poor welding, uneven substrates or installation in strong winds often cause leakage within a short period. Identifying these errors allows us to provide the optimal solution for each project.

Uneven welds, insufficient heating or contamination are the main causes of leakage. SKSumo inspects 100% of weld seams using air-pressure testing to ensure watertightness according to ASTM standards.

Improper substrate preparation creates abnormal stress points. SKSumo inspects the foundation multiple times before hdpe waterproofing installation to prevent blistering during operation.

Strong winds easily cause the membrane to curl, twist or deform. SKSumo follows strict procedures with temporary sandbag anchoring and directional control to ensure safe installation.

Choosing the right solution ensures membrane quality and long-term durability. SKSumo recommends solutions based on foundation conditions, water load, technical standards and real operating environments for each hdpe waterproofing installation project.

Deep reservoirs or continuous-water structures require anchoring trenches and thicker membranes. Shrimp ponds prioritize installation speed and easy repair. SKSumo recommends tailored solutions for each model.

Each project has a different load level. For general housing construction, HDPE membrane 1.2-1.5mm thick is preferred for projects with high water pressure, while small auxiliary projects can use 0.5-1.0mm.

All SKSumo projects are accepted according to ASTM and GRI standards. Warranty documents, tensile tests and leak-tightness reports are fully prepared for each structure.

Dual-track welders and certified technicians are essential to ensure proper weld seam quality. This is why SKSumo maintains a well-trained and experienced installation team.

SKSumo recommends hdpe waterproofing installation methods based on many years of experience and the specific requirements of each structure.

Normally use HDPE membrane 0.75-1mm, construction on compressed ground, lined with geotextile. Welding lines are arranged far from aeration equipment areas to avoid vibration.

With the priority of aesthetics and flatness, HDPE film with thickness of 1.2-1.5mm is the suitable choice. The welding seam is processed neatly and folds are limited to ensure aesthetics.

Typically 2.0mm thick membranes, anchor grooves and geotextile linings are required, and the construction process follows a full inspection process to ensure environmental safety.

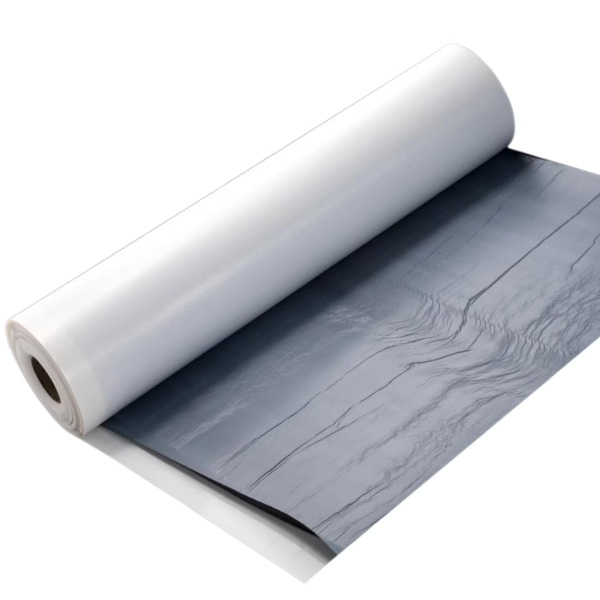

The concrete floor is polished flat, with curved corners and is covered with a 1.2–1.5mm thick self-adhesive HDPE waterproofing membrane. The welding seam is tightly controlled to prevent groundwater from seeping into the structure.

The cost of hdpe waterproofing installation depends on membrane thickness, area, ground conditions and acceptance standards. SKSumo specializes in waterproofing residential projects with transparent quotes and proposes the most cost-effective solutions without affecting the quality of construction.

Key factors include membrane thickness, substrate type, installation complexity, number of weld seams and inspection requirements.

Proper foundation preparation, optimized layout direction, reduced seam intersections and choosing an experienced contractor help significantly lower costs.

The best solution depends on the compatibility between project conditions and installation techniques. SKSumo Đà Nẵng provides end-to-end services from consulting, supplying materials, to installing and accepting hdpe waterproofing installation, ensuring durability, safety and long-term structural performance.

Yes. High humidity reduces weld quality and increases the risk of trapped moisture. Installation should only be done when the ground is dry and the weather is stable.

Yes. Welders require a stable power source to maintain correct temperature. Voltage fluctuations are a common cause of weak or incomplete welds.

No. Localized punctures can be repaired using a patch of the same thickness and thermal welding. Replacement is only necessary when the damage is extensive.

Weld seams involve heat-softened material, so any error in temperature, pressure or contamination can form gaps. This is why dual-track welding and vacuum testing are essential.

Not always. However, in areas with sharp stones or high loads, geotextile significantly reduces friction and increases membrane lifespan compared to installing directly on soil.