Many believe that installing metal sheets can completely prevent water penetration, but in reality, effectiveness depends on the materials, climate, and installation technique. This article will help you understand the concept correctly, compare it with waterproof paint, and identify when it should be applied for maximum results.

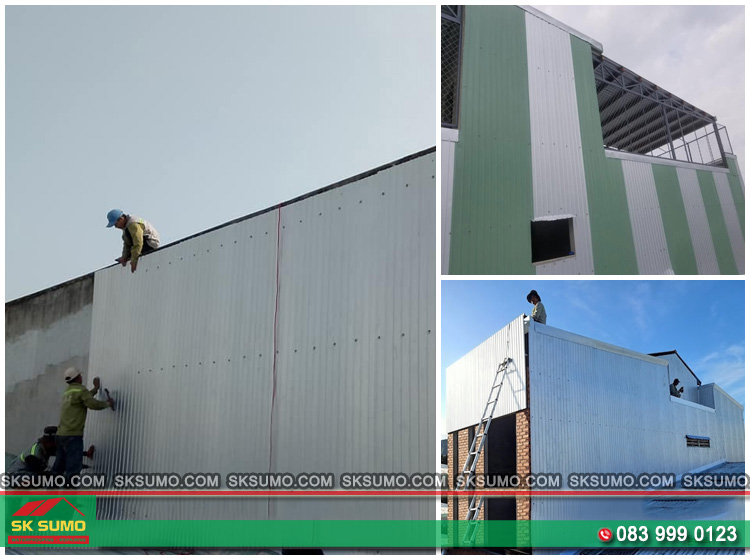

Waterproof metal cladding is a method that uses cold steel sheets, insulated metal panels, or galvanized sheets to cover exterior walls, preventing rainwater from penetrating the plaster and inner paint layers. This solution is widely used for west-facing houses, areas with heavy rainfall, or regions with high humidity.

The main applications include:

• Protecting exterior walls from mold, peeling paint, and long-term moisture.

• Reducing wall temperature to improve heat resistance and extend paint life.

• Minimizing repainting costs under harsh climate conditions.

As this method aims to block direct water infiltration, many wonder whether they should install waterproof metal cladding instead of relying solely on waterproof paint-something that needs to be analyzed in later sections.

Ordinary roofing sheets only protect the roof from sun and rain, whereas waterproof cladding is designed to prevent water from seeping into wall structures. The main differences are:

Waterproof cladding is typically used when:

• The wall faces west or south, directly exposed to sunlight and driving rain.

• The house is located in central or southwestern Vietnam, where rainy seasons are long. In particular, in Đà Nẵng - a coastal city with humid monsoon weather and frequent rainfall-this solution is very common.

• The wall is old or cracked and cannot be fully repaired with waterproof paint.

In these cases, installing waterproof metal sheets not only protects the wall but also enhances insulation and reduces long-term maintenance costs.

One of the most common misunderstandings is that waterproof cladding can completely prevent water penetration. In reality, it only resists direct rainwater, not absolute moisture if the wall already has cracks or damp foundations. Water can still seep through gaps, sheet edges, or joints between the wall and roof if not properly sealed with adhesive or silicone waterproofing.

The performance of waterproof metal sheets depends greatly on sunlight exposure, rain direction, and humidity levels. In central Vietnam, prolonged heavy rain can cause moisture accumulation behind the metal layer, leading to mold if ventilation gaps are missing. Meanwhile, in southern regions, a combination of waterproof paint and insulated metal sheets is more effective to prevent both water and heat.

Not every building requires waterproof metal cladding. For high-rise buildings or walls already coated with premium waterproof paint, cladding can reduce aesthetics or complicate maintenance. In well-ventilated areas with little rain exposure, treating cracks and applying waterproof coating is sufficient. Therefore, it’s important to assess the wall condition carefully before deciding.

In terms of durability, metal cladding can last 15-20 years, while waterproof paint typically needs reapplication every 5-7 years. However, if the metal corrodes or has open edges, water may still seep in. Conversely, waterproof paint adheres well to flat surfaces but struggles against driving rain or large cracks.

→ The most effective solution is combining both: applying waterproof paint inside and metal cladding outside for maximum protection.

The cost of metal cladding ranges from 350,000-600,000 VND/m², depending on type and thickness, while waterproof paint costs about 60,000-150,000 VND/m². Although the initial investment is higher, metal cladding significantly reduces repainting and repair costs over time, especially in harsh climates.

Waterproof paint preserves the building’s original architecture, while metal cladding offers a more modern, industrial style. However, improper installation can add weight and cause internal dampness. It’s recommended to use galvanized frames, keeping a 2-3 cm gap for airflow and moisture prevention.

The notable benefits include:

Thanks to these advantages, the question “should you install waterproof metal sheets?” becomes valid, especially in humid or hot regions.

Some drawbacks to keep in mind:

Therefore, before installation, ensure flat surfaces, choose cold steel or PU-insulated sheets, and use anti-rust screws for long-term effectiveness.

The lifespan of waterproof metal cladding depends on:

When done correctly, the cladding can last 15-25 years, offering major savings compared to repainting.

Selection should match local climate and sun exposure. In central Vietnam, where storms and humidity are high, use double-layer cold steel or PU-insulated sheets with anti-corrosion coating. In northern regions, prefer galvanized steel to keep walls dry.

For west- or south-facing walls, use light-colored sheets like silver, cream, or gray to reflect heat. For northeast-facing walls, thinner sheets (0.35-0.4 mm) combined with waterproof paint are enough.

This tailored approach clarifies whether you should install waterproof metal sheets depending on each climate condition.

The optimal thickness for waterproof metal cladding is 0.4-0.5 mm-strong yet easy to install. Thinner sheets rust easily, while thicker ones increase costs and wall weight.

Choose light or neutral colors to reduce heat absorption. Dark colors like navy, brown, or black trap more heat, making interiors warmer. Powder-coated or PVDF-coated sheets maintain color and durability over time.

If you’re considering installing waterproof metal cladding for sun-exposed walls, prioritize UV-resistant and heat-reflective sheets to save energy and improve comfort.

Trusted brands in the market include:

When choosing, request authentic certification and standard thickness to ensure lasting waterproof performance-essential when deciding whether to install waterproof metal cladding instead of paint.

According to construction material experts, metal cladding is ideal for:

In harsh climates, this solution protects the plaster and paint layers, extending wall lifespan up to 20 years-a practical answer to whether you should install waterproof metal sheets or just repaint.

Modern buildings often combine waterproof paint and metal sheets for dual protection:

This hybrid method prevents direct rain contact and keeps the inner wall dry, especially effective in central and southwestern Vietnam. If budget allows, this is the best long-term approach to install waterproof metal sheets effectively.

For walls with deep cracks or decay, cladding alone won’t fix the issue. More durable methods include:

For weak walls, apply cement-based waterproof paint first, then metal sheets to reduce load-ensuring both aesthetic appeal and long-term moisture protection.

Many assume metal cladding can make walls completely waterproof. However, results depend on installation quality, sheet type, and local climate. Claims of “absolute waterproofing” are inaccurate since metal only prevents direct rainfall, not internal moisture. Thus, proper understanding is crucial when evaluating whether to install waterproof metal sheets.

Evaluate using these criteria:

If these factors are ensured, waterproof metal cladding can reach up to 90% effectiveness, matching or exceeding high-end waterproof paints.

Depending on wall condition, climate, and budget, metal cladding can be a highly effective solution, especially in rainy areas. However, it shouldn’t fully replace waterproof paint. The best approach is to combine both, select suitable materials, and ensure proper installation for durability.

→ In short, metal cladding is not an “absolute shield,” but a smart reinforcement for aging or weather-exposed walls. When properly applied, it remains a worthwhile investment for long-term protection.

High-quality cold steel or aluminum-zinc-coated sheets generally resist rust for 10-15 years. However, if sheet edges or screws are unsealed, oxidation may occur after long-term rain exposure.

It depends on the design. Flat or wood-patterned cladding can create a modern look. Choosing harmonious colors with the roof and windows enhances visual appeal.

Installing waterproof cladding requires precision in measurement, drilling, and sealing joints, so professional installation is recommended. Mistakes can trap water and cause wall mold.

The average cost ranges from 350,000-600,000 VND/m², depending on material type, framing, and installation complexity. High-rise projects or angled walls may incur an additional 10-15%.

Absolutely. Many experts recommend painting first, then installing metal sheets to maximize protection and prevent moisture buildup behind the panels. This is the most effective and durable solution to the question of whether you should install waterproof metal sheets.